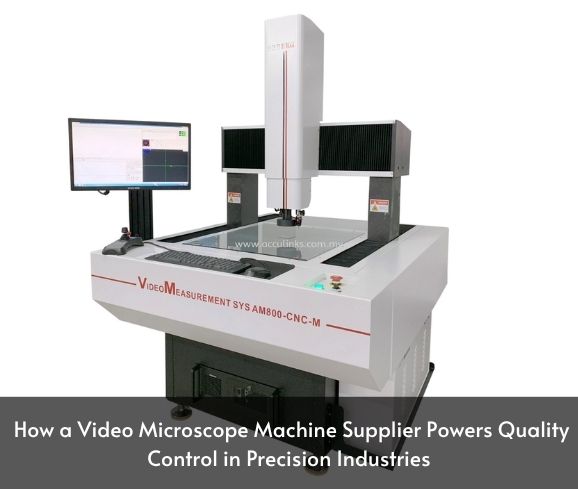

Why Precision Industries Depend on a Reliable Video Microscope Machine Supplier

Precision industries such as aerospace, automotive, and electronics demand meticulous quality control to ensure product integrity and safety. A dependable video microscope machine supplier provides the advanced imaging tools necessary for detailed inspection and analysis. These tools enable manufacturers to detect minute defects, measure components with high accuracy, and maintain consistent production standards.

Hansvue, a leading video microscope machine supplier, offers a range of digital microscopes designed to meet the stringent requirements of precision industries. Their equipment facilitates non-contact, high-resolution inspections, ensuring that even the smallest imperfections are identified and addressed promptly.

Role of a Video Microscope Machine Supplier in Aerospace and Automotive QC

In the aerospace and automotive sectors, component failure can have catastrophic consequences. Therefore, quality control processes must be rigorous and precise. A specialized video microscope machine supplier like Hansvue provides the tools necessary for thorough inspections of critical components such as turbine blades, engine parts, and electronic circuits.

Hansvue’s digital microscopes enable engineers to perform detailed analyses of surface finishes, welds, and microstructures. This capability is essential for identifying potential issues before they lead to failures, thereby enhancing safety and reliability in these high-stakes industries.

High-Resolution Imaging from a Certified Video Microscope Machine Supplier

High-resolution imaging is crucial for detecting defects that are invisible to the naked eye. A certified video microscope machine supplier ensures that their equipment delivers the clarity and detail required for such inspections. Hansvue’s digital microscopes are equipped with advanced optics and sensors that provide sharp, detailed images, facilitating accurate assessments of components.

These high-resolution capabilities are particularly beneficial in industries where precision is paramount. For instance, in semiconductor manufacturing, even the slightest defect can render a chip unusable. Hansvue’s microscopes allow for the early detection of such issues, saving time and resources.

Real-Time Inspection Capabilities by a Professional Video Microscope Machine Supplier

In fast-paced manufacturing environments, real-time inspection capabilities are essential for maintaining production efficiency. A professional video microscope machine supplier like Hansvue offers equipment that provides live imaging, enabling immediate analysis and decision-making.

Hansvue’s digital microscopes support real-time video feeds, allowing quality control personnel to monitor processes and identify defects as they occur. This immediacy reduces downtime and ensures that corrective actions can be taken promptly, maintaining the flow of production without compromising quality.

How Hansvue Supports Advanced Manufacturing as a Video Microscope Machine Supplier

Advanced manufacturing techniques require equally advanced inspection tools. As a dedicated video microscope machine supplier, Hansvue provides solutions that integrate seamlessly with modern manufacturing processes. Their digital microscopes are designed to accommodate various inspection needs, from simple visual checks to complex metrology tasks.

Hansvue’s commitment to innovation ensures that their equipment evolves alongside manufacturing technologies. By offering customizable features and software integrations, they enable manufacturers to tailor their inspection systems to specific requirements, enhancing overall efficiency and product quality.

Video Microscope Machine Supplier Tools for Non-Destructive Testing (NDT)

Non-destructive testing is vital for assessing the integrity of components without causing damage. A proficient video microscope machine supplier provides tools that facilitate such evaluations. Hansvue’s digital microscopes are instrumental in NDT applications, offering high-resolution imaging that reveals internal and surface defects without altering the test subject.

These tools are particularly useful in industries where component preservation is crucial.For example, in the aerospace sector, inspecting critical parts without compromising their usability is essential.Hansvue’s equipment enables such inspections, ensuring safety and compliance with industry standards.

Performance Metrics to Evaluate Your Video Microscope Machine Supplier

When selecting a video microscope machine supplier, it’s important to assess their performance based on several key metrics:

Image Quality: The clarity and resolution of images produced.

Ease of Use: User-friendly interfaces and controls.

Customization: Ability to tailor equipment to specific needs.

Support Services: Availability of training, maintenance, and technical assistance.

Integration Capabilities: Compatibility with existing systems and processes.

Hansvue excels in these areas, offering high-quality imaging, intuitive controls, customizable options, comprehensive support, and seamless integration, making them a top choice for precision industries.

Building a Long-Term Relationship with a Video Microscope Machine Supplier Like Hansvue

Establishing a long-term partnership with a reliable video microscope machine supplier ensures consistent quality and support. Hansvue fosters such relationships by providing ongoing assistance, updates, and training to adapt to evolving industry needs.

Their commitment to customer satisfaction and continuous improvement means that clients can rely on Hansvue not just for equipment, but also for expertise and innovation. This collaborative approach contributes to sustained success in quality control and manufacturing excellence.

Conclusion

In precision industries, the role of a competent video microscope machine supplier is indispensable. Hansvue stands out by offering advanced, reliable, and customizable digital microscopes that meet the rigorous demands of quality control. Their dedication to innovation, customer support, and industry-specific solutions makes them a trusted partner in achieving manufacturing excellence.

For more information on Hansvue’s digital microscope offerings, visit their official website: Hansvue Digital Microscopes.